formula for calculating work in progress inventory

Deduct the cost of raw material from this figure that is on hand at the end of the accounting period to determine the costs of materials consumed during the accounting period. Ad Start your free trial stop wasting time on inventory spreadsheets.

All You Need To Know About Wip Inventory

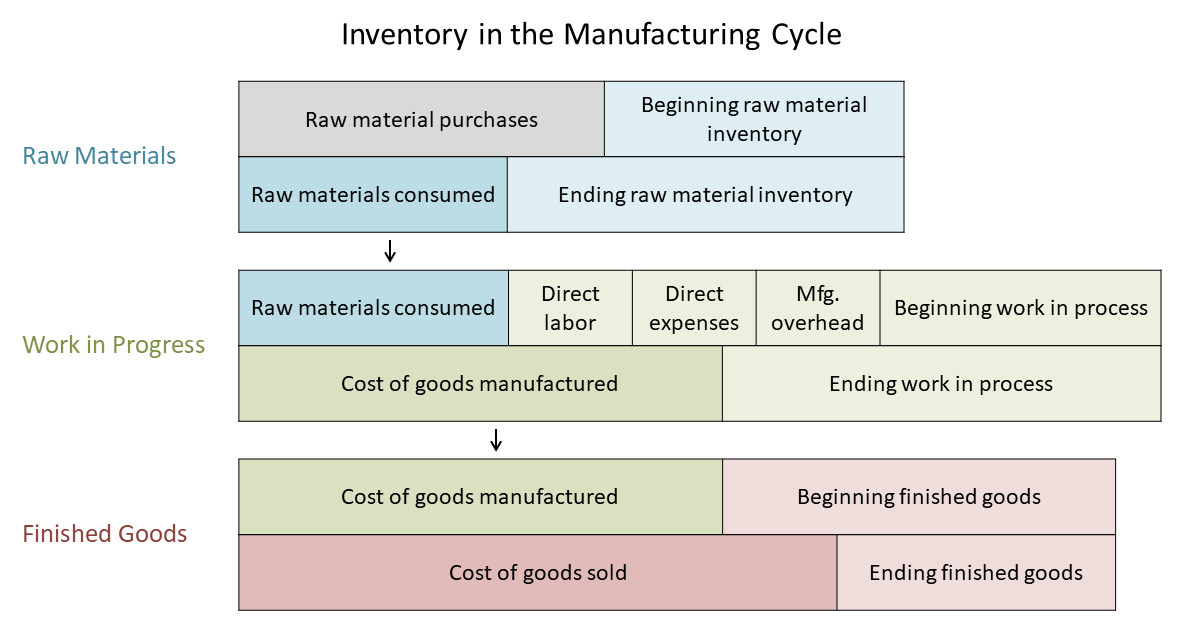

Consisting of all raw materials work-in-progress and finished goods that a company has accumulated.

. Using the steps above here are examples for the gross profit retail and work in process methods for. It is also not yet finished goods because more. Ending inventory WIP formula.

Suppose the XYZ widget company has an initial WIP inventory of 10000 for the year. To calculate your in-process inventory the following WIP inventory formula is followed. Referred to as Cost Completion on job task lines WIP Sales Recognized Sales - Billable Invoiced Price.

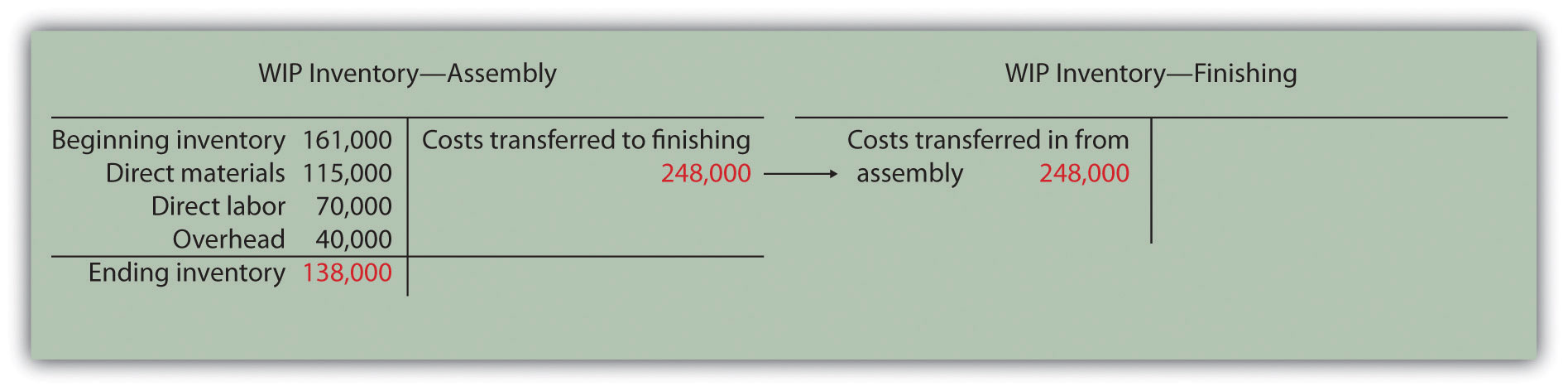

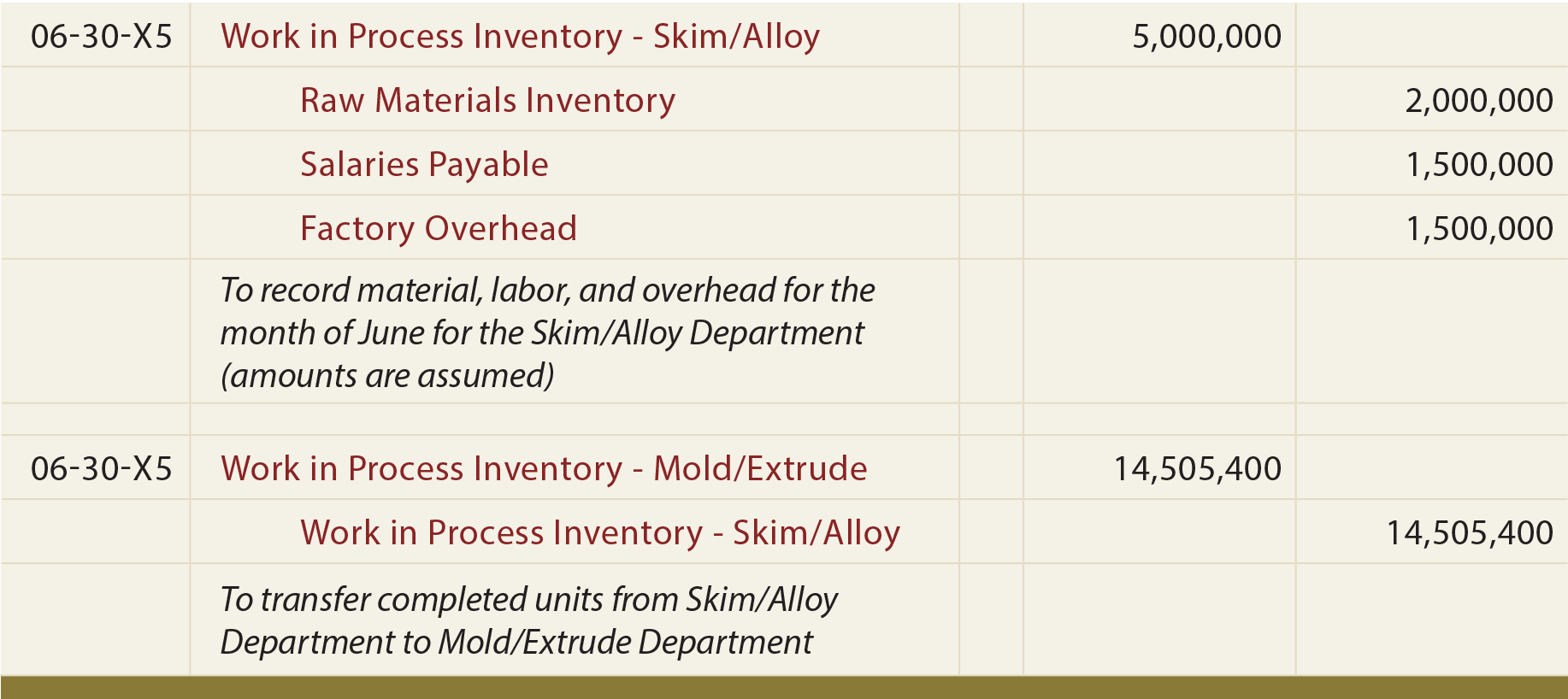

This account of inventory like the work-in-progress may include direct labor material and manufacturing overhead. The general ledger account used to track work in progress is the work in progress inventory account. This account represents the costs of resources used but not yet turned into completed products.

On the other hand work in progress is often used in construction and other service businesses and refers to the progress of a project and how much it is costing compared to percentage of completion. All costs associated with the work. Work in process WIP inventory refers to materials that are waiting to be assembled and sold.

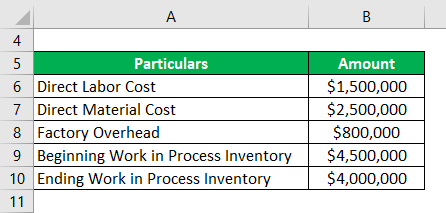

Imagine BlueCart Coffee Co. On the other hand work in progress takes time and cannot be termed a current asset as it is not anticipated to be converted into cash soon. Below is the data table.

It is often deemed the most illiquid of all current assets and thus it is excluded from the numerator in the quick ratio calculation. Using this WIP formula businesses can calculate how much work in process inventory they will have left over at the end of the accounting period. WIP inventory includes the cost of raw materials labor and overhead costs needed to manufacture a finished product.

Inventory Formula Example 1. Work in progress is a stage in between the raw material and finished goods. Work in progress WIP is the part of inventory that is currently being worked on and is yet in the production process.

When these terms are used by businesses selling a physical product both mean the same thing. In this case for example consider any manufactured goods as work in process. Once the period is over and the figure is calculated this number becomes the beginning work in process.

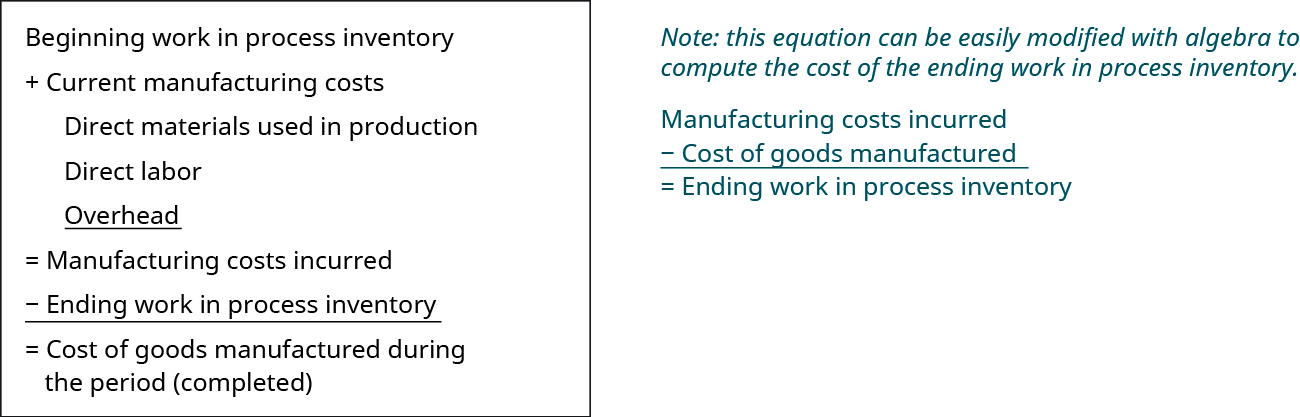

Since WIP inventory takes up space and cant be sold for a profit its generally a best. Abnormal loss- Physical units produced are multiplied by the degree of completion. Ending inventory using work in process Beginning WIP Manufacturing costs Cost of goods manufactured.

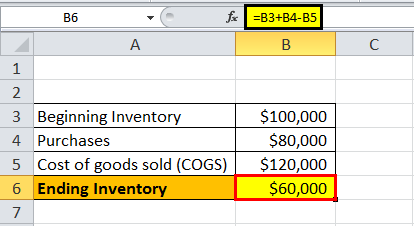

It is no longer raw material because it has undergone some processing in the production process. During the remaining financial year the company has made purchases amounting 20000 and during that time on the companys income statement the cost of goods sold is 40000. Calculating work in process inventory is a complicated and time consuming process because it requires an assessment of the percentage of work completed and the cost associated with it.

Work in Process vs. Work in process inventory examples. Build an app instead.

Work In Process and Work In Progress Inventory are often used in place of each other with discrepancies between them occurring depending on the industry they are being used in. Calculating Your Work-In-Process Inventory. Percentage of Completion Usage Total Costs Budget Total Costs.

Ending WIP Inventory Beginning WIP Inventory Manufacturing Costs - Cost of Finished Goods. As a result of this you would have to freeze the production process until you have bought the materials to use. The formula for calculating WIP inventory is.

In accounting a work in progress WIP account is an inventory account that includes goods that are in the process of being produced but are not yet finished. Percentage of completion calculations recognize revenue proportionally based on the percentage of completion that is usage total costs vs. The beginning WIP inventory cost refers to the previous accounting periods asset section of the balance sheet.

Let say company A has an opening inventory balance of 50000 for the month of July. During the span of the time the company incurs manufacturing costs of 250000 and produces finished goods from the raw material costing 240000. For example a building expected to have 30 floors and has five.

If we calculate the overall WIP inventory of the company is 10000 plus 250000. Beginning WIP Manufacturing costs - Cost of goods manufactured. For example you have run out of materials to create a certain amount of products.

The calculation of ending work in process is. Different businesses have different costs but generally an accountant would compile all the raw material costs direct labor costs and factory overhead associated with the. It is one of the inventory accounts commonly used to track the flow of costs in a.

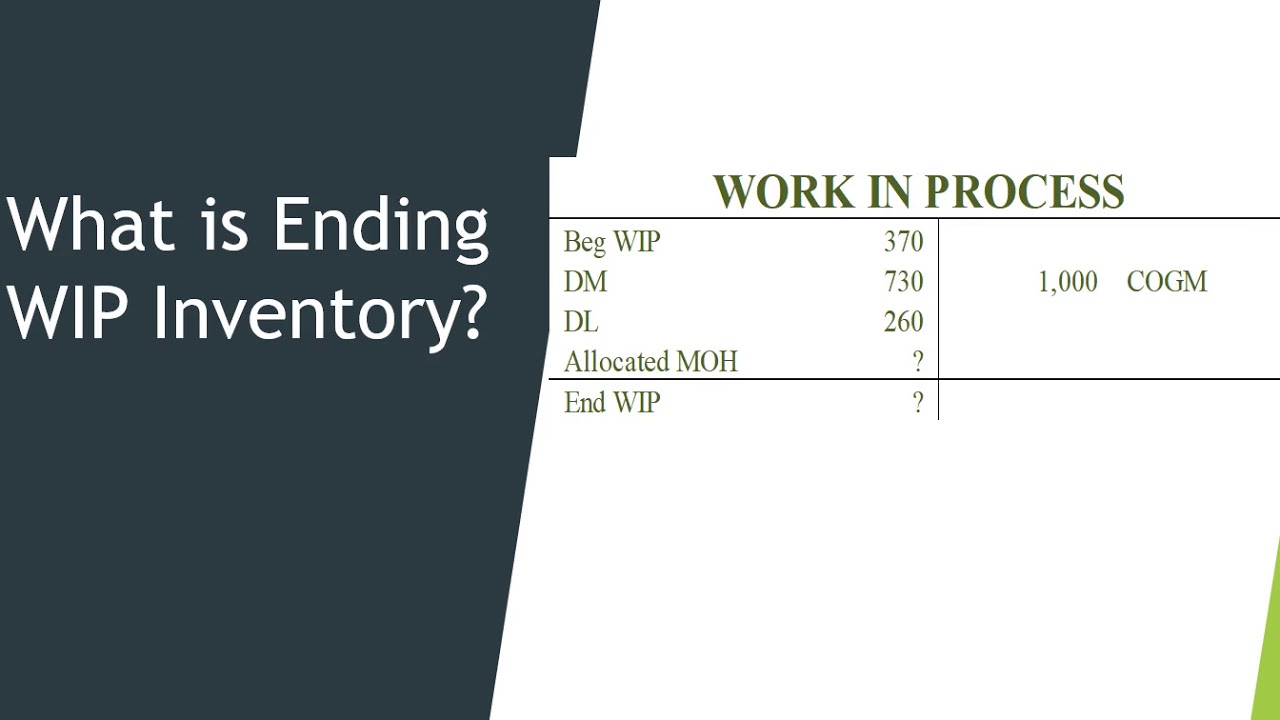

The formula for calculating the WIP inventory is. The work in process formula is. WIP is calculated as a sum of WIP inventory total direct labor costs and allocated overhead costs.

The factory overhead costs can be calculated for the accounting period. The amount of ending work in process must be derived as part of the period-end closing process and is also useful for tracking the volume of production activity. This calculation typically includes the cost of raw materials being used a portion of the labor and a portion of the factory overhead to get a good idea of what costs have been covered thus far in production and what.

Therefore many companies only calculate work in process inventory close to the end of a specific reporting period to minimize time spent on calculations. There is an interplay between the inventory account and the cost of goods sold in the income statement. Beginning WIP Inventory Manufacturing Costs COGM Ending WIP Inventory.

Abnormal gain- Physical units 100 complete. How to Calculate Ending Work In Process Inventory. Ending WIP Inventory Beginning WIP Inventory Manufacturing Costs COGM.

Definition formula and benefits. Additionally its essential that businesses and organizations accurately report costs associated with production for insight into performance and efficiency. The labor costs for the accounting period should be calculated.

Order forms payment processing stock management more. Amortization Formula and Calculation. To calculate the value of your work-in-progress inventory you simply add together the cost of all the components you have consumed to reach this point in your production.

Another example would be one of your production equipment has broken down so your processes have come to a halt. In this article well explore what work in process is the formula to calculate work-in-process inventory and how work-in-process differs from work in progress within the production process. Has a beginning work in process inventory for the quarter of 10000.

Ending work in process. Examples of how to calculate ending inventory. WIP Inventory Example 3.

Work in progress inventory or WIP for short refers to the total cost of unfinished goods that are currently in production. Lets use a best coffee roaster as an example. Under this method the cost of completed units is calculated by multiplying production expressed in terms of equivalent units.

Work In Process Wip Inventory Youtube

Use The Job Order Costing Method To Trace The Flow Of Product Costs Through The Inventory Accounts Principles Of Accounting Volume 2 Managerial Accounting

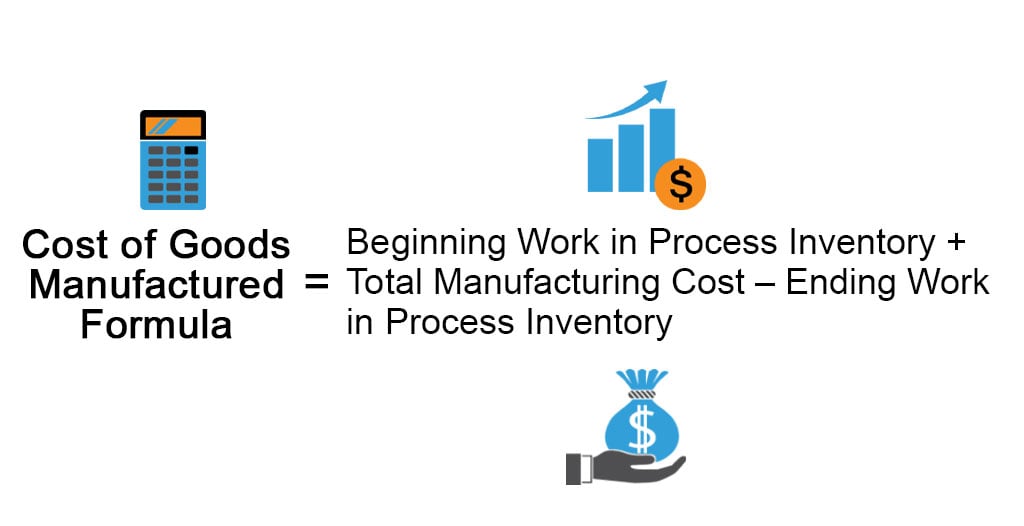

Cost Of Goods Manufactured Formula Examples With Excel Template

Work In Process Inventory Formula Wip Inventory Definition

Cost Allocation To Completed Units And Units In Process Principlesofaccounting Com

Wip Inventory Definition Examples Of Work In Progress Inventory

Ending Inventory Formula Step By Step Calculation Examples

Ending Inventory Formula Step By Step Calculation Examples

How To Calculate Manufacturing Work In Progress Wip Solutionbuggy

How To Calculate Finished Goods Inventory

What Is Work In Process Wip Inventory How To Calculate It Ware2go

Solved Data Table Gallons Work In Process Inventory Chegg Com

Work In Progress Wip Definition Example Finance Strategists

Cost Of Goods Manufactured Formula Examples With Excel Template

What Is A Work In Progress Wip 2020 Robinhood

Understanding How Wip Work In Progress Is Calculated In Sap With Example Tech Concept Hub